NLMK Group R&D Center

> 4 500 m²

a laboratory area in which unique equipment is installed

> 50 employees

qualified high-class experts

> 1000 test

categories

NLMK Group R&D Center is a modern science facility that can be referred to like facilities to be as good as the first-rate world research institutes.

R&D Center involves the units engaged in the following activities: classic metallurgy, chemical analysis, special analysis and fine structural researches, heat treatment, mechanical property testing, coating and characterization, welding and stamping, metallurgical process simulation.

Global presence

The main laboratory base for conducting research is located at the Lipetsk site of NLMK (Lipetsk, Russia), the competence center for computer modeling and development of premium coatings is located in La Louvier (Belgium). The R&D project office is located in Lipetsk and Moscow.

History of development

R&D Center was established in 2019 but its science advancement history goes back to the early days of foundation of Novolopetsk Steel – a lead site of NLML Group.

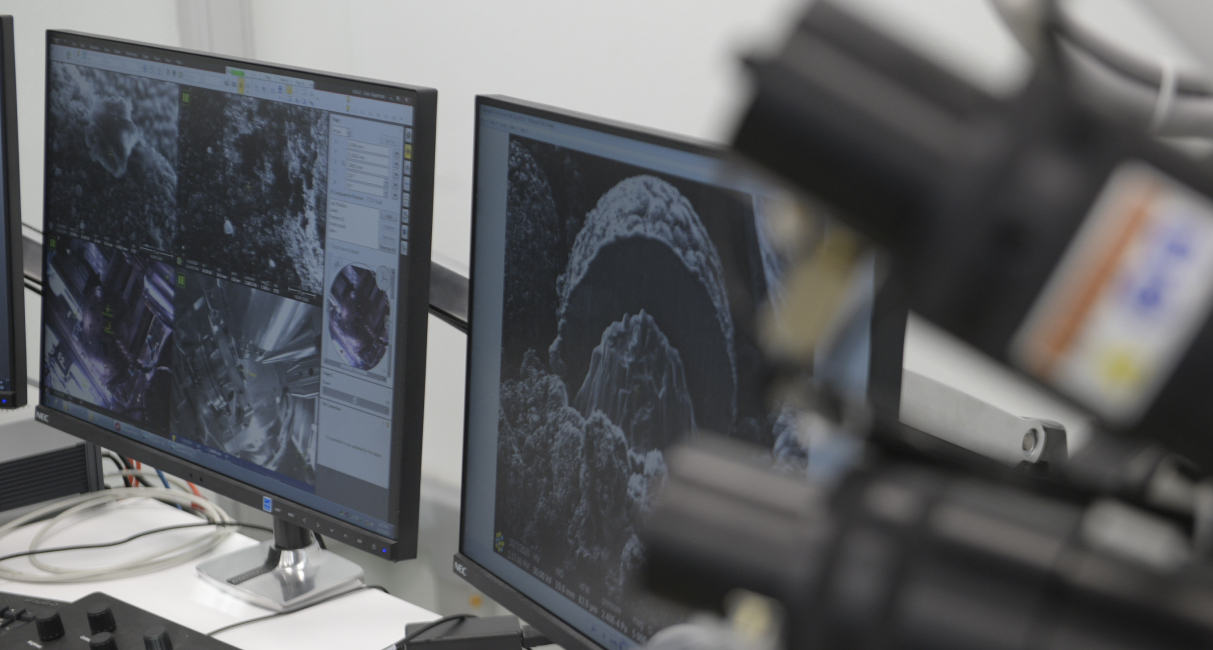

Nowadays, the R&D Center personnel employ physical material analysis and test techniques including transmission electron microscopy, X-ray diffractometry, spectral analysis, and metallographic analysis methods. A wide variety of equipment is used for macro-, micro-, and nano-level testing.

One of the basic R&D Center tasks is to create new types of high-performance products and to reduce ecological load factors within the areas in which NLMK Group operates.

Center work

There are more than 40 units of the state-of-the-art high-precision equipment from the best world brands used by the company’s R&D Center.

Any in-depth studies can be conducted in the shortest possible time for developing new break-through items and technologies. Scores of prototypes can be created in the R&D Center laboratories with hundreds of steel heat and deformation treatment techniques tested.

We say with pride that there is a creative crew of scientists and high-rate R&D Center equipment. A Talos F200i transmission electron microscope installed at the microstructure testing laboratory was the first one in the Russian Federation and in the CIS member states. Continuous annealing processes are simulated using a CAS unit (Japan) to be an exclusive one in the Russian Federation. A unique NLMK-developed complete cycle to simulate melting, hot and cold rolling, heat treatment, microstructure and properties characterization processes is a very basis for creating new materials capable to meet the most complicated customer’s requirements.

The research team consists of Russian and foreign scientists, as well as talented post-graduates and students

from Russia, Poland, Belgium, Italy, Spain and India possessing practical material development skills and steel production qualifications.

R&D Center collaborates and works together with other leading facilities and research institutes in Russia and overseas in order to create new technologies and products.

About NLMK Group

NLMK Group Corporate websiteNLMK Group is a vertically integrated metallurgical company in Russia and it is one of the most effective steel producers in the world.

NLMK Group metal products find their market in various industries ranged from construction and mechanical engineering to power engineering and offshore wind engineering.

There are NLMK business assets in Russia, Europe and in the USA. The company has the annual steel output exceeding 14.5 million tons.

Design approach R&D

01

Idea

The major R&D team task is to test new ideas and to transform them into finished NLMK Group products. This is done to reduce project implementation expenditure, to speed up development and adoption of solutions, as well as to reduce innovation activity risks.

Innovative company activity ideas come to the R&D Center idea bank through the main two-path route:

Customer inquiry for new product types / market trend analysis

Proper ideas and developments arising in the course of scientific and research activities