Tasks and areas of activity

The microstructure analysis team test physically simulated samples being checked for compliance with parameters set out by the customer.

State-of-the-art and high-precision equipment employed can be used for measuring the following parameters

>500 sqm

laboratory area

30+

pieces of equipment

1000+

measurement types

Virtual tour

of the laboratory

Key Laboratory Equipment

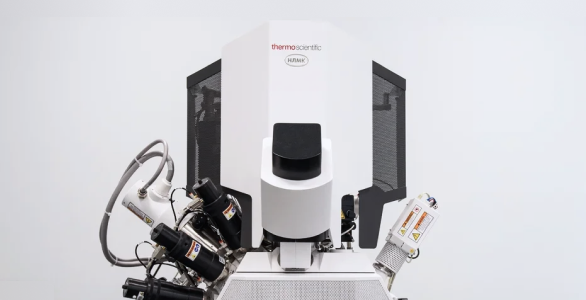

all equipmentTalos F200i transmission electron microscope

SmartLab SE X-ray diffractometer

Scios scanning electron microscope