Создаем совершенную сталь[EN]

NLMK Group

In-House R&D Center

A modern scientific complex of the level of the world's leading research institutes, where an international team of experienced researchers and young scientists is engaged in the development of new products and research in the field of industry and the environment.

Our developments are applied

in key strategic

industries and directions

Development of a portfolio of premium products with high added value. A wide range of our own competencies, which covers the full cycle of metallurgical production for all areas of human activity

Directions of activities

01

Automotive industry

02

Mechanical engineering

03

Household appliances

04

Construction

05

Power engineering

06

Ecology and environment

07

Computer-aided engineering

Geography

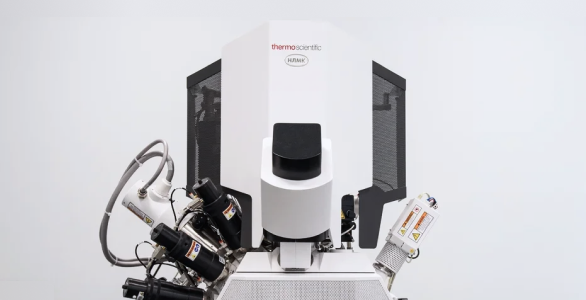

NLMK R&D Center enjoys the most up-to-date equipment

Innovative equipment of the R&D Center supports comprehensive researching at macro-, micro- and nano- levels

Equipment of the centerAffiliate network

The partner network of the R&D center is constantly expanding. The list of our key partners includes leading scientific schools, research institutes, technology and consulting companies

All partnersWe welcome talented professionals to contribute into the global-scale projects

Internship lasting from 1 month to 1 year in the project office and high-tech laboratories of the center

Real-life work experience in one of the largest metallurgical companies in the world

Internship programs